Processes

The processes we use

This allows us to manufacture virtually any mechanical part that might be required, guaranteeing a consistently high level of quality for your precision parts – from a single source and at competitive prices – while simplifying the process of sourcing and managing suppliers and saving you money.

The next few pages give you an idea of our manufacturing capabilities. We would be delighted to have the opportunity to demonstrate our expertise in person.

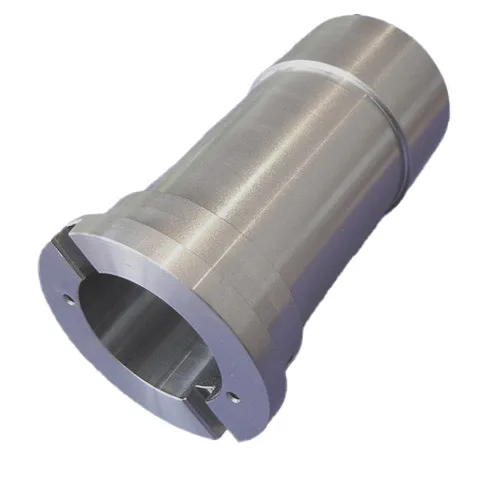

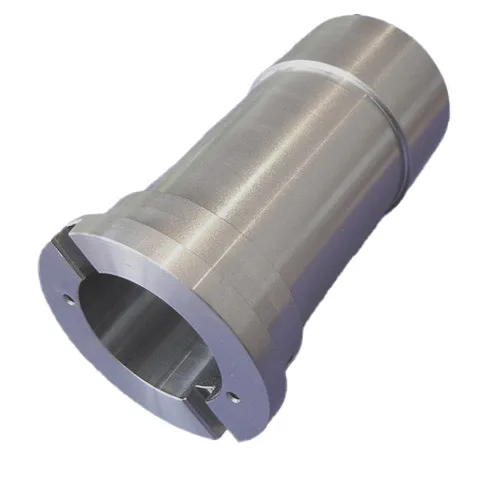

Our turning systems are powerful and precise.

Turning

Thanks to our capacity, we can maintain our high level of performance even when handling larger quantities and high machining volumes. Combining milling and turning also enables us to meet high requirements in terms of shape and position tolerances:

Our fleet of machinery: Turning

| Designation | Ø to | Length up to |

|---|---|---|

| Mazak QT Smart 350 | 420 mm | 1.000 mm |

| DMG CTX 510 | 460 mm | 1.000 mm |

| DMG CTX 600 | 500 mm | 1.000 mm |

| DMG CTX 650 V1 | 600 mm | 1.150 mm |

| DMG CTX 650 V3 | 600 mm | 1.150 mm |

| DMG CTX 650 V3 | 600 mm | 1.150 mm |

| DMG CLX 750 V4 | 700 mm | 1.300 mm |

| DMG CTX 620 | 600 mm | 2.000 mm |

| DMG CTX 620 | 600 mm | 2.000 mm |

| DMG CTX 620 | 600 mm | 2.000 mm |

| DMG CTX 620 | 600 mm | 2.000 mm |

| DMG CTX beta 2000 | 600 mm | 2.000 mm |

| DMG CTX beta 2000 | 600 mm | 2.000 mm |

| Heyligenstaedt Heynumat 25U-3000 | 780 mm | 3.000 mm |

| Doosan Puma 700 XLY | 750 mm | 5.050 mm |

| Boehringer DUS | 500 mm | 6.000 mm |

| Boehringer DUS 800 | 500 mm | 8.000 mm |

| Boehringer, Weiler, Voest | 600 mm | 2.000 mm |

Our milling systems are powerful and precise.

Milling

Our fleet of machinery: Milling

| Designation | X = | Y = | Z = |

|---|---|---|---|

| Zayer BF 3 4000 Bed milling machine | 3.600 mm | 1.016 mm | 1.016 mm |

| Mazak VTC 300 4-axis vertical machining centre |

1.740 mm | 760 mm | 660 mm |

| Mazak VTC800/30SR with rotary indexing head | 3.000 mm | 800 mm | 720 mm |

| Mazak VTC800/30SR with rotary indexing head | 3.000 mm | 800 mm | 720 mm |

| DMG DMC 160U with dual pallet changer, horizontal/vertical machining centre | 1.600 mm | 1.250 mm | 1.000 mm |

| DMG DMC 80H with dual pallet changer, horizontal machining centre | 800 mm | 710 mm | 710 mm |

| DMG DMC 80H with dual pallet changer, horizontal machining centre | 800 mm | 710 mm | 710 mm |

| Klopp, TOS | 400 mm | 1.000 mm |

We harden and straighten efficiently and precisely

Hardening/Straightening

This enables us to offer short throughput times and a monitored high level of quality even when working with hardened components. Our straightening press allows us to correct any distortion caused by the hardening process without delay. Additional heat and surface treatments are carried out by other accredited specialists, with priority given to firms local to us.

By selecting suitable companies and undertaking continuous quality monitoring, we can offer good quality at competitive prices at all times.

Here is a selection of possible treatments:

Quenching and tempering and annealing

Case and salt bath hardening

Nitriding and ferritic nitrocarburizing

Galvanising and phosphating

Bronzing

Anodising and coating

Painting/varnishing/lacquering and coating

Our fleet of machinery: Hardening

| Designation | Ø to | Length up to |

|---|---|---|

| EFD induction hardening machine (surface hardness depth in accordance with DIN up to 10 mm) |

500 mm | 6.000 mm |

Our fleet of machinery: Tempering

| Designation | Temperature | |

|---|---|---|

| Tempering furnace | up to 300° C |

Our fleet of machinery: Straightening

| Designation | Weight | |

|---|---|---|

| MAE S250 RH | 250 t |

We provide high-performance and precise grinding.

Grinding/finishing

Superfinishing also lets us produce unbeatable surface finishes.

We mainly apply centreless grinding to machine bushings and shorter shafts.

Our fleet of machinery: Cylindrical grinding

| Kind | Designation | Ø | Length |

|---|---|---|---|

| CNC | Schaudt PF71 | 700 mm | 3.000 mm |

| CNC | Danobat HG72 | 640 mm | 2.000 mm |

| Between centres | Schmaltz R6/6000 | 500 mm | 6.000 mm |

| Between centres | Roweig SA6/3000 | 400 mm | 3.000 mm |

| Between centres | Roweig SA6/1200 | 350 mm | 1.200 mm |

| Between centres | Tachella | 350 mm | 1.000 mm |

| Centreless | Herminghausen, Estarta | 250 mm | 250 mm |

Our fleet of machinery: Surface grinding

| Kind | Designation | X = | Y = |

|---|---|---|---|

| CNC | Danobat RTM 1600 | 1.600 mm | 800 mm |

Our fleet of machinery: Honing

| Kind | Designation | Ø | Length |

|---|---|---|---|

| CNC | Sunnen SV25 | up to 150 mm | up to 800 mm |

WE OFFER FURTHER ACTIVITIES

Other machining tasks

The demagnetisation of components is becoming increasingly important, particularly in the mining industry. We can provide detailed testing and measurement reports on request and coordinate acceptance tests by certification bodies (DB, DNV, LROS, GL, etc.)

Read on for some examples of the services we provide:

| Kind | What | Detail |

|---|---|---|

| Sawing | Kasto | up to 260 mm in diameter |

| Sawing | Kasto | up to 560 mm in diameter |

| Thread rolling | Bad Düben, Pee-Wee | up to M 100 |

| Thread rolling | on shafts up to 6,000 mm long and 500 mm in diameter | |

| Welding, brazing | for all techniques | |

| Demagnetising | Tunnel demagnetiser | up to 500 mm in diameter for all lengths |

| Measuring/testing | Zeiss Contura 3D measuring machine, Zeiss SCANMAX coordinator measuring equipment, hardness tester, surface measuring device, layer thickness measuring device, X-ray machine, etc. Crack detection system (magnetic particle inspection method) |

|

| Labelling | Needle embossing machine |